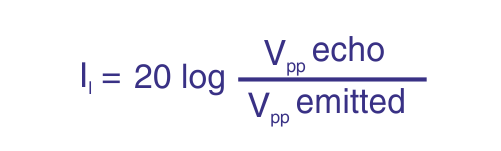

Insertion loss characterizes the sensitivity of a transducer and is defined as:

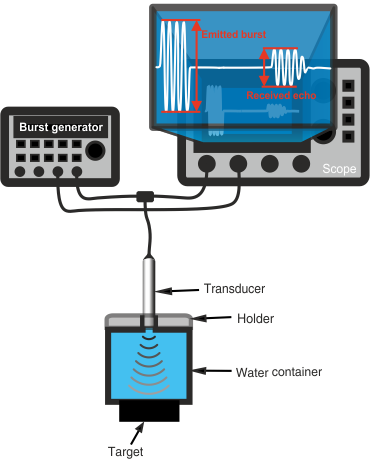

To measure a transducer's insertion loss, an ultrasonic burst is emitted. The same transducer receives an echo from a plane target that is perpendicular to the beam and has an acoustic impedance significantly different from the liquid used for transmission. The voltage ratio between the echo and the emitted burst, expressed in logarithmic form, is the Insertion Loss (IL).

Signal Processing's transducers typically have an IL between 6 and 20 dB, depending on the type of transducer.

Required equipment:

- Burst generator

- Amplifier (optional)

- Oscilloscope

- Two 50 Ω coaxial cables + 1 T-connector

- Water container with transducer holder

- Target (stainless steel recommended)